Polymer, fibre and bulk characterisation

Polymer Characterisation

Polymer Characterisation

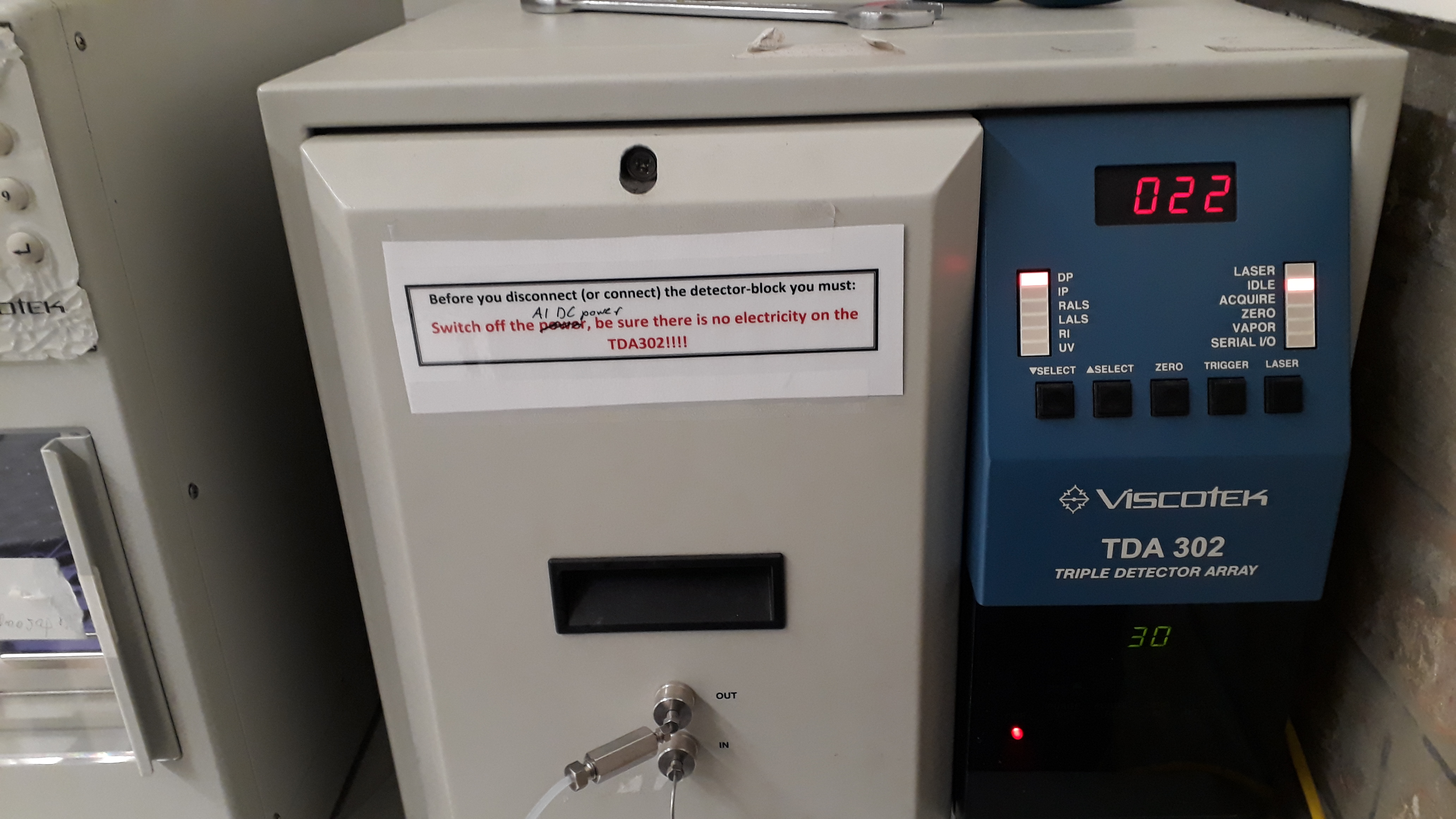

Gel permeation chromatography (GPC)

GPC equipped with triple detection system (Viscotek TDA 302) is used for the characterisation of the molecular weight (distribution) of water-soluble polymers.

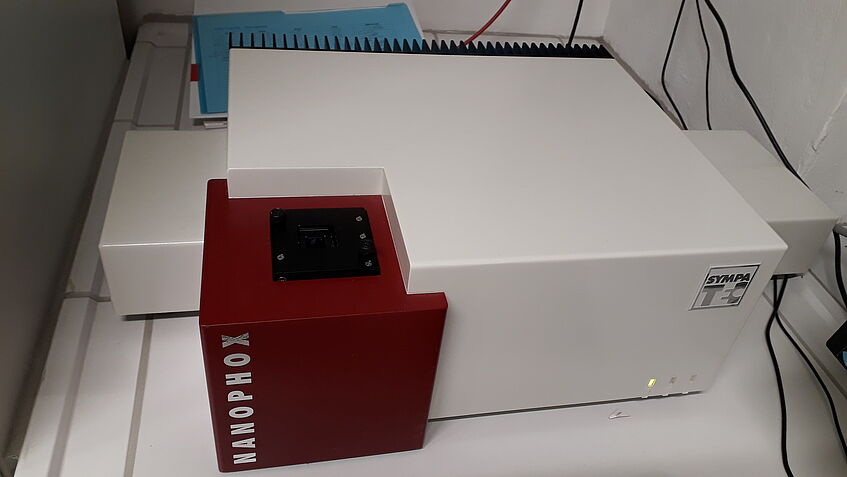

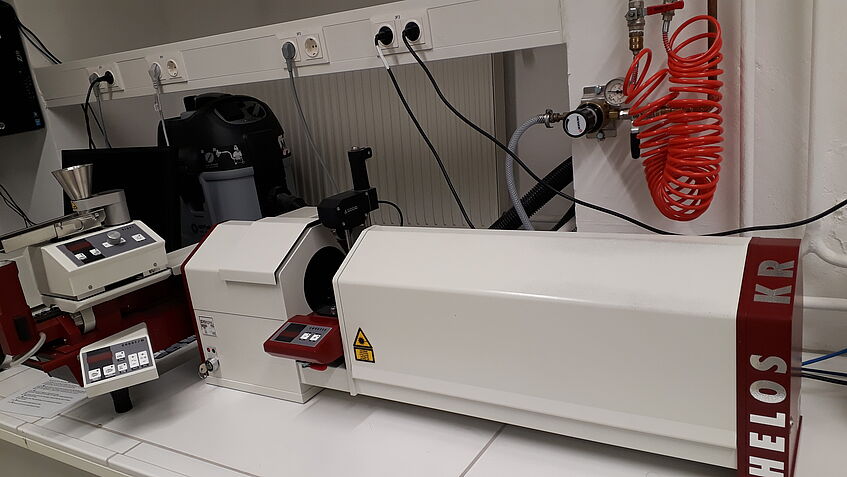

Particle Size

Nanoparticles

The size of nanoparticles from 0.5 nm to 10 µm is analyzed using dynamic light scattering with a Nanophox (Sympatec). For larger particles (0.1 µm to 8.75 mm) Helos KR (Sympatec) is used

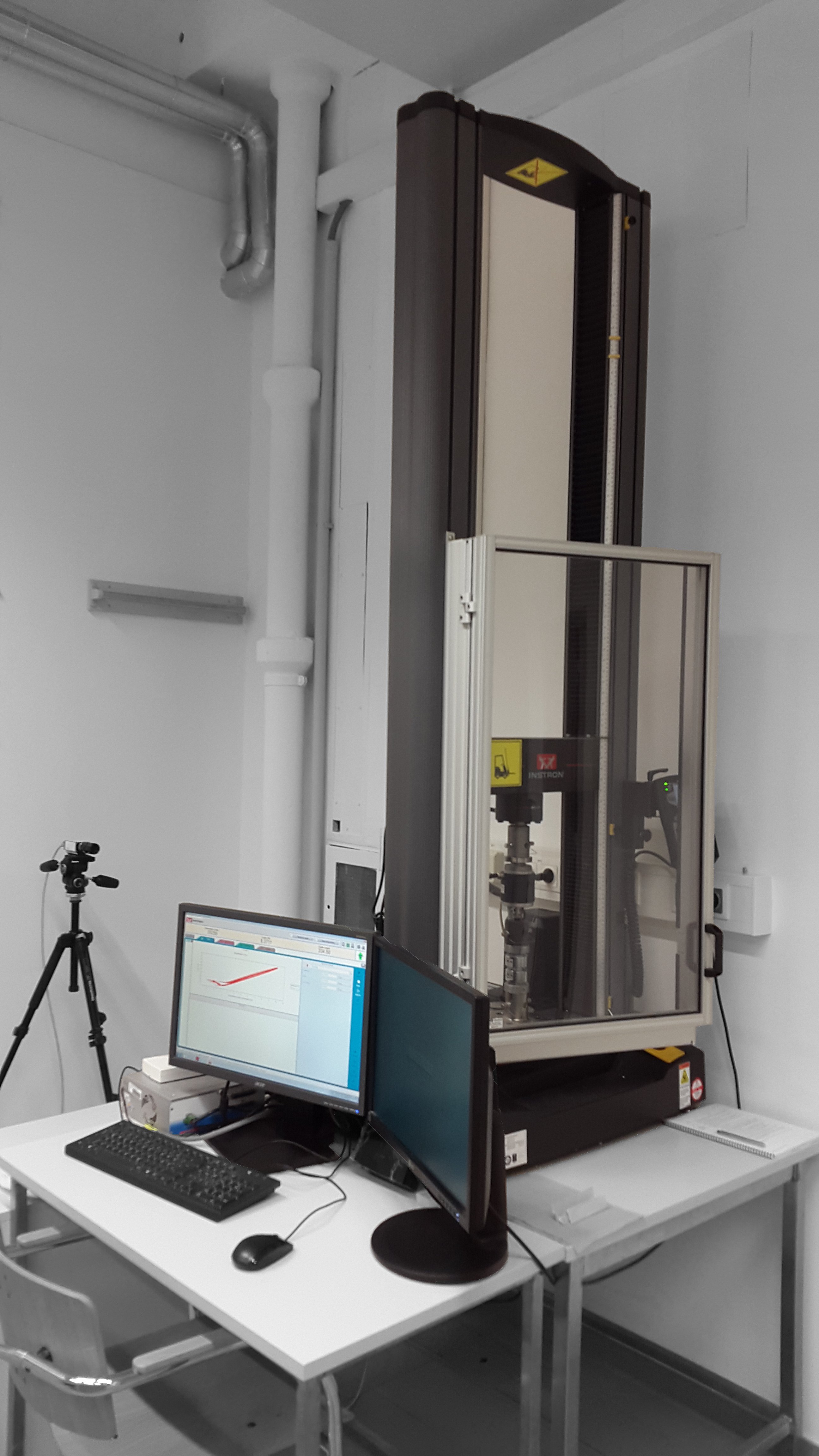

Mechanical Characterisation of Materials

Mechanical Testing

Two universal testframes (Instron 3345 & 5969) are used for the mechanical characterization of polymer and composite sample in tensile, compression or bending mode.

Single Fibre-Pull-Out Testing Machine

Single Fibre-Pull-Out Testing Machine

Our single fibre pull-out device was designed by BAM Berlin. The device uses a piezo-actuator (with a displacement resolution of a few nanometres) and a piezo force transducer (with a resolution of 0.1 mN). A microscope is fitted to allow optical observations during testing. We use this instrument to determine strength and modulus of thin reinforcing fibres, incl. strength dependence of fibres at short gauge lengths as well as adhesion and friction properties of single fibre composites.

Viscoelastic and rheological properties

Rheometer

A capillary rheometer [TYPE, MANUFACTURER] and rotational rheometer (TA Discvoery HR2) are used for determination of viscosities with various geometries (capillary, plate-plate, cone-plate, Cup & Bob).

Moisture Uptake Behaviour

Moisture Uptake Behaviour

Dynamic vapour sorption (DVS)

DVS (Intrinsic, Surface Measurement Systems) allows automated, rapid and accurate gravimetric measurements of moisture uptake in solid materials (e.g., polymers, paper, natural fibres, composites and porous materials) over a wide temperature range using dynamic environment control and ultra-sensitive recording microbalance with resolution of ~0.1μg. The ability to work with very small sample sizes combined with dynamic vapour flows reduces the time to measure moisture sorption isotherms from weeks or months to hours or days.

Gas Permeability

Gas Permeability

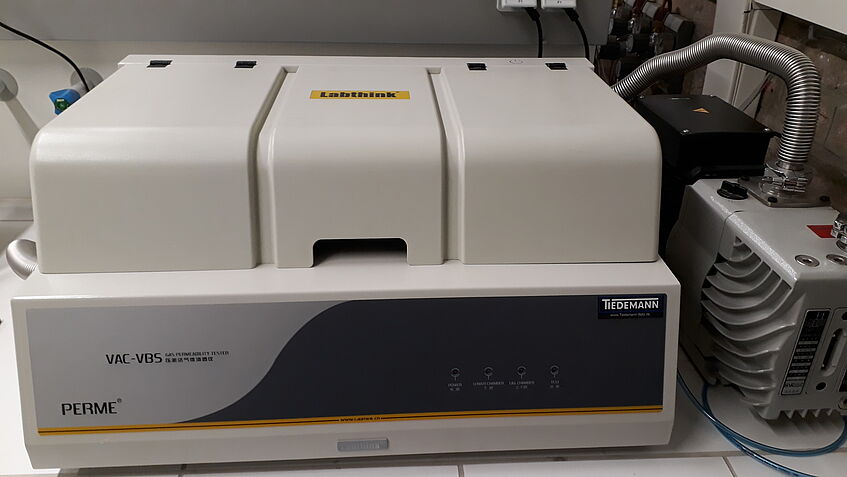

Gas permeability of porous media and polymer films (LabThink VAC VBS & W3 031), e.g. oxygen or water vapour, is an important feature, in particular of (food) packaging materials. Both, O2 and H2O vapour are detrimental for the expiration date of food, but usually (polymer or paper) materials employed constitute either a barrier for O2 or H2O vapour.

Characterisation of Porous Media

Characterisation of Porous Media

Mercury porosimetry

Mercury porosimetry allows for simultaneous measurement of pore volume distribution, limiting pore throat diameter, permeability distribution and electrical conductivity of porous materials following the penetration of pores with mercury. Porous samples are placed in the sample cell and mercury is forced into pores. Mercury is non-wetting and thus the pressure applied to the mercury can be used to determine the diameter of the pores being filled. Incremental increases in the applied pressure result in the determination of the pore volume distribution. Application of a pressure gradient across the sample induces mercury flow through pores of a specific diameter and a permeability distribution can be developed. The applied pressure corresponding to the onset of mercury flow indicates the limiting pore throat size.